As we have already discussed in Greases Explained, a grease is made up of a mineral or synthetic base oil, a thickener, and an additive package.

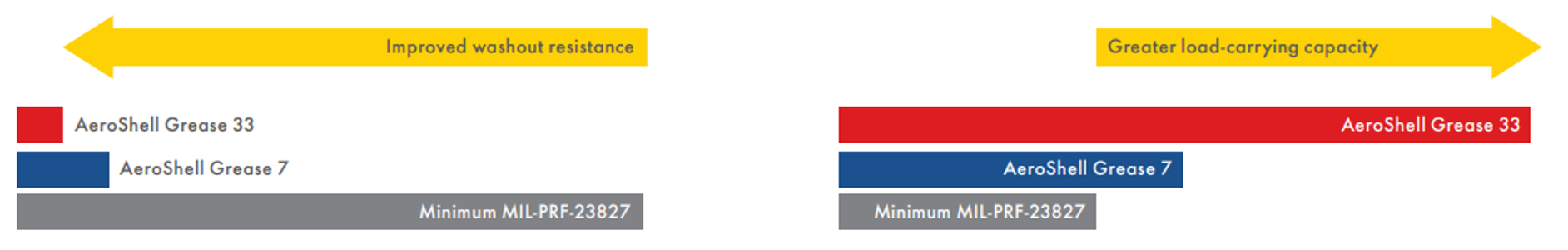

Clay-based thickeners, such as Microgel® in AeroShell Grease 7 and 22, have been used in aircraft since the 1960s owing to their good water-resistance and high-temperature properties. They have served the aviation industry well and they will continue to serve, where high temperature performance is required.

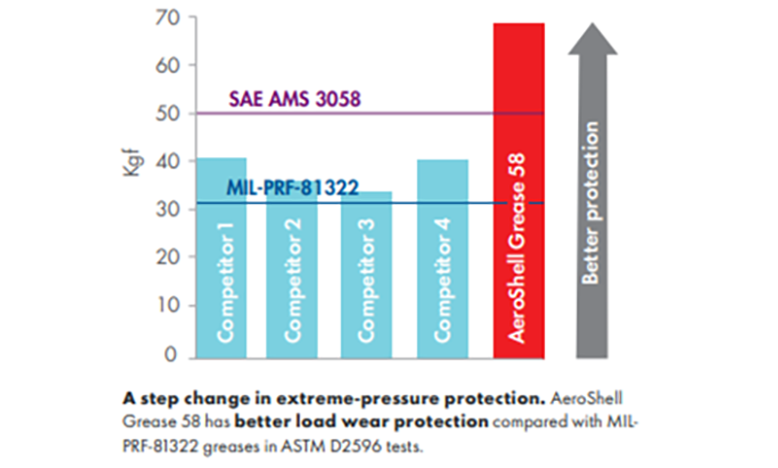

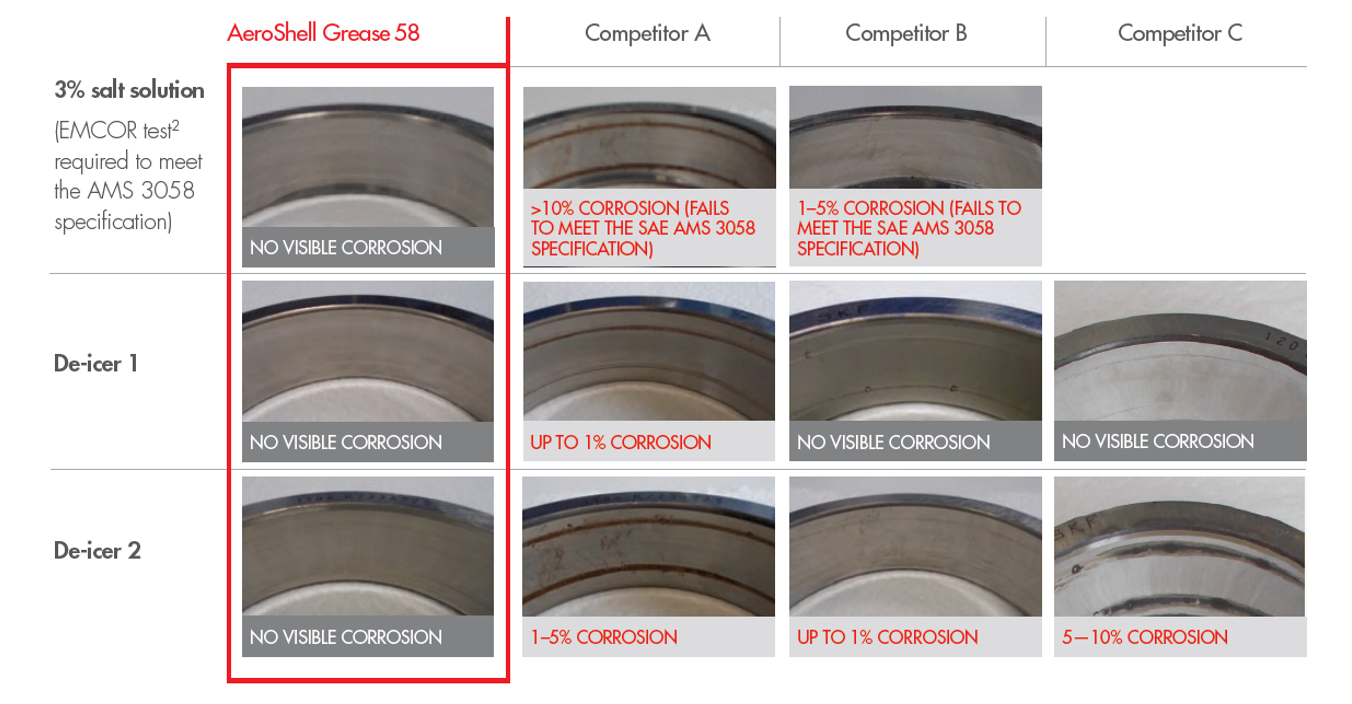

However, over time the requirements for greases became more and more complex requiring the use of a wider range of sophisticated additives. At the same time, the customer expectation regarding durability was also rising.