Quick View

It is important to note that greases can also provide extensive preservation qualities across the aircraft.

AeroShell Grease 6 is a general purpose, Microgel thickened grease composed of a mineral oil. It possesses good all-round properties within a limited range and inhibits against oxidation and corrosion. Additionally, AeroShell Grease 6 has good water resistance and low noise capability.

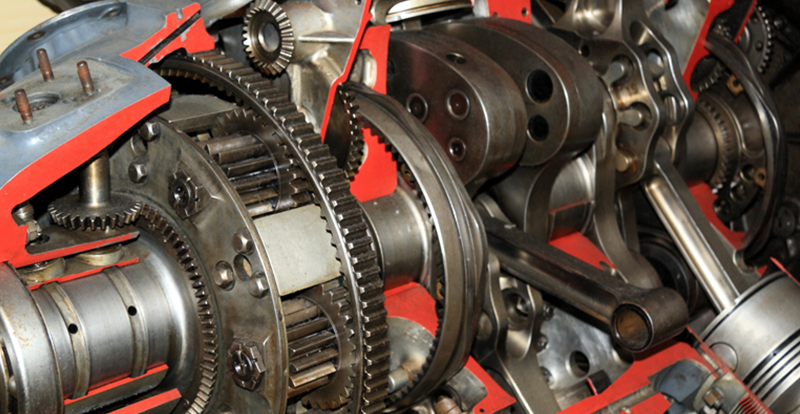

Approved to MIL-PRF-24139A, AeroShell Grease 6 is used in anti-friction bearings, gearboxes and plain bearings within the temperature range of –40°C to +121°C. Additionally, AeroShell Grease 6 is an ideal propeller grease, both for flying and storage.

AeroShell Grease 22 is a versatile, multipurpose grease designed to extend the lives of wheel bearings operating under high loads, speeds and temperature ranges. This grease can help to extend component life and reduce maintenance costs through its excellent load-carrying capacity and resistance to wear, corrosion, oxidation and water washout.

During storage and aircraft down time, AeroShell Grease 22 continues to keep aircraft wheel bearings, engine accessories, control systems, actuators, screw jacks, servomechanisms, electric motors, instruments, airframe lubrication, hinge pins, static joints and landing gear free from corrosion and ready to fly.