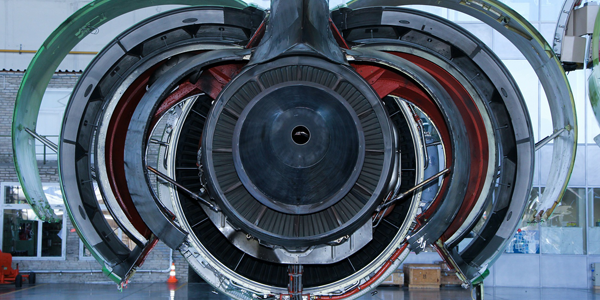

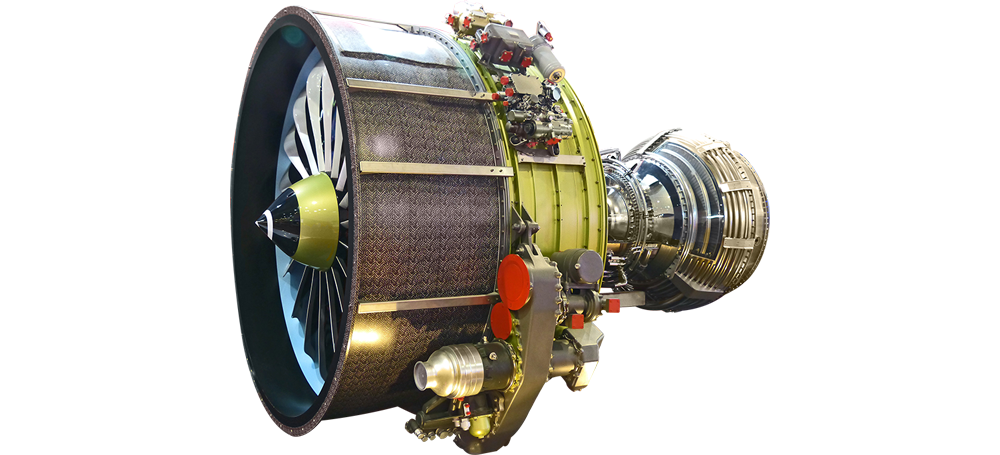

There are three main functions of a turbine engine oil (TEO). Firstly, they lubricate the engine, including the gearbox, shafts and associated accessories, protecting them from damage and ensuring smooth operation while running.

In addition to this, the various additive packages in turbine engine oil protect the components from corrosion, and filter contaminants in the engine such as carbon deposits formed from a process known as coking.

In addition to this, the various additive packages in turbine engine oil protect the components from corrosion, and filter contaminants in the engine such as carbon deposits formed from a process known as coking.

Finally, and probably the most important benefit from a TEO is their use as a heat transfer fluid, cooling the engine in temperatures reaching 1000°c, in turn extending the life of the oil up to 25,000 hours of operation.