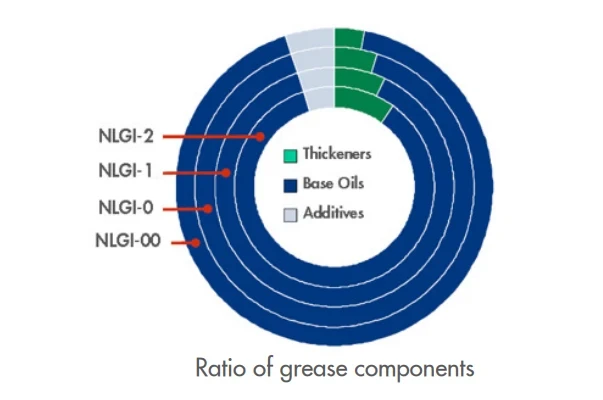

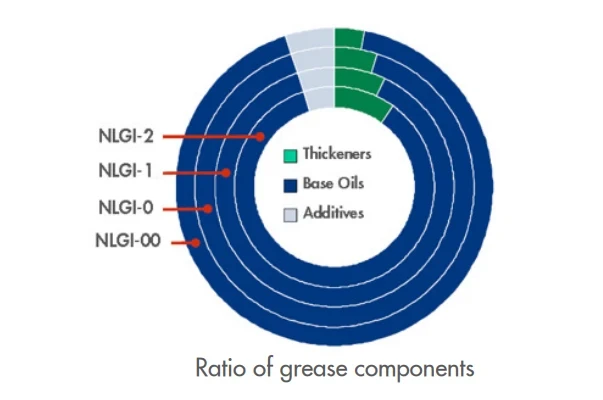

Ratio of Grease Components

NLGI 2 grease is widely recognized for its moderate consistency, making it ideal for aerospace and industrial applications. NLGI, which stands for the National Lubricating Grease Institute, employs the NLGI grade as a means of measuring and rating the consistency or hardness of grease. The NLGI classification consists of 9 grades, with 000 being the most fluid and 6 being the hardest. NLGI 2 has an ASTM worked (60 stokes) penetration at 25 degrees centigrade of 265 to 295 tenths of a millimetre. NLGI Grade 2 is one of the most commonly used grades within the aerospace industry and could be described as having a moderate consistency. A few of the applications for which this grade of grease could be suitable for include wheels bearings, gear systems, hydraulic components and heavy machinery.

Ratio of Grease Components

NLGI 2 Grease Comparison Table

| NLGI Grade | Description | Similar Consistency to |

| 000 | Fluid | Cooking Oil |

| 00 | Semi Fluid | Apple Sauce |

| 0 | Very Soft | Mustard |

| 1 | Soft | Tomato Puree |

| 2 | Medium | Peanut Butter |

| 3 | Medium Hard | Margarine |

| 4 | Hard | Frozen Yoghurt |

| 5 | Very Hard | Smooth Pate |

| 6 | Block | Cheddar Cheese |

EP stands for extreme pressure. An EP grease is one that is designed to be used in high pressure conditions. An EP2 grease will be available to NLGI Grade 2. The 2 in EP2 refers to the NLGI grade (2).

NLGI Grade 1 is a very soft grease, similar to the consistency of tomato paste. NLGI Grade 2 is a soft grease with a consistency similar to peanut butter. The lower the NLGI grade, the softer the grease.

For example:

To learn more about what grease is made of, how it's formulated, and how different consistencies compare, check out this detailed article on the components and types of grease.

By understanding both the NLGI number and full grease specifications, users can ensure optimal machinery performance and longer equipment life.

NLGI 2 grease offers exceptional versatility across a wide range of industries. Beyond its common use in wheel bearings and electric motors, it is ideal for high-speed rotating machinery, robotic slides, appliance motors, and dental drills operating in high-temperature environments.

For users needing guidance on technical properties, it’s important to review the NLGI 2 grease specifications for details on temperature ranges, chemical compatibility, and application suitability.