Industrial Grease Explained: Composition, Characteristics, and Use

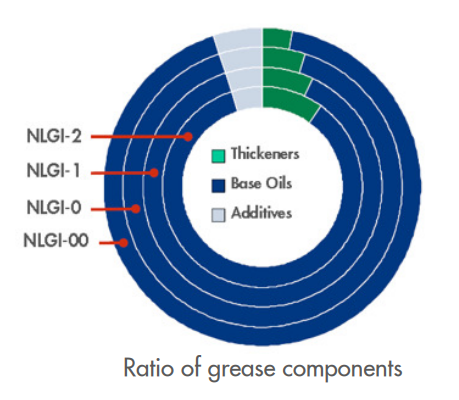

Greases are generally made up of three components: base fluid, thickener and additives.

Choosing the Right Industrial Grease for Specific Applications

Selecting the right industrial grease starts with understanding the specific demands of your equipment and operating environment. Unlike general-purpose lubricants, industrial greases are formulated for targeted use cases—ranging from high-speed bearings to equipment exposed to moisture, heavy loads, or extreme temperatures.

Each grease characteristic, such as viscosity, thickener type, and additive package, plays a vital role in determining how the grease will perform under different mechanical stresses. For example, soap-thickened greases are commonly used because of their excellent shear stability and compatibility with various base oils and additives. In contrast, non-soap thickeners may be preferred for applications requiring greater resistance to high temperatures or chemical exposure.

By evaluating these characteristics in relation to your application, you can ensure that the selected industrial grease offers optimal protection, minimises wear, and extends the service life of your machinery. For more detail on consistency levels and performance expectations, explore our guide to NLGI 2 industrial grease.

High-Temperature and Extreme Condition Performance

In demanding industrial environments, grease must do more than just lubricate—it must maintain its integrity under extreme conditions. Unlike circulating oils, industrial grease lacks the ability to dissipate heat through convection, making it more susceptible to thermal degradation such as oxidation and carbonisation.

To perform reliably, industrial grease must retain its essential grease characteristics like consistency, film strength, and shear stability even when exposed to high temperatures, heavy loads, or intense pressure. This is especially important in applications such as enclosed gear systems, high-speed bearings, or machinery that operates intermittently or under shock loading.

Some industrial greases are enhanced with solid lubricants like molybdenum disulfide or graphite, which remain suspended in the grease and provide additional protection when traditional oil films would fail. These formulations help reduce wear, resist breakdown, and extend equipment lifespan in the most punishing conditions. For help identifying the right formulation by specification or brand, check our Grease Cross Reference guide.

Frequently Asked Questions About Industrial Grease

What is the best grease for industrial bearings?

Lithium grease is one of the most commonly used types of industrial grease for ball and roller bearings. It offers excellent versatility, resists high temperatures, and performs reliably under various load conditions. These grease characteristics make it ideal for use in industrial machinery, automotive components, and heavy-duty applications.What are the four types of grease?

The four general types of industrial grease are: lithium-based, calcium-based, aluminium complex, and polyurea. Each type differs in terms of grease characteristics such as water resistance, load capacity, and thermal stability. Choosing the right one depends on your specific application needs.Which is thicker, 0 or 00 grease?

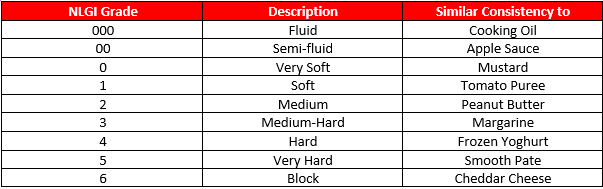

On the NLGI consistency scale, 00 grease is less thick than 0 grease. The scale ranges from 000 (very fluid) to 6 (block-like). Lower numbers are softer and more pumpable, while higher numbers are firmer and used in more stationary applications. These classifications are key grease characteristics to consider when selecting the proper product.