For over 60 years, Loctite have been producing a variety of threadlockers suitable for a wide range of applications. As their expertise has grown, so has the demand for new and innovative product adjustments, leading to a wider range of product available. But how do you know which threadlocker is right for the job at hand?

What is a threadlocker?

A threadlocker is a liquid adhesive designed to secure fasteners from loosening between maintenance cycles. At Loctite, the threadlocker has become widely known as the “red bottle” due to its distinctive look.

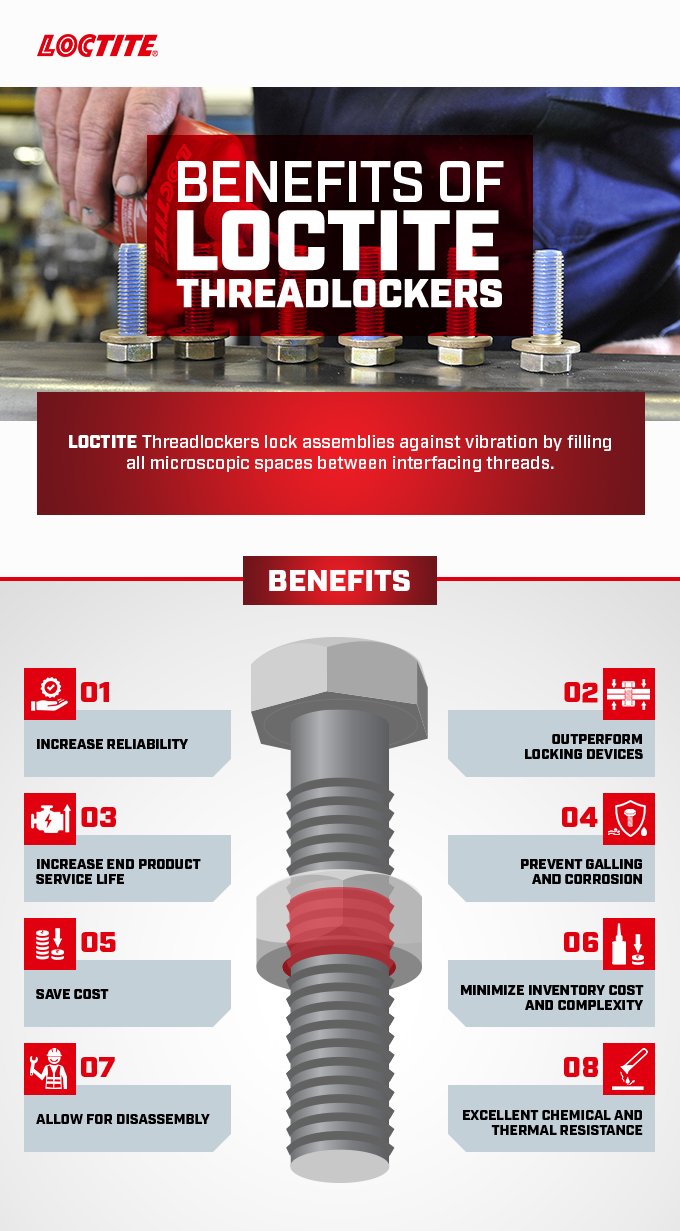

Did you know that there is only 15% metal-to-metal contact in the interior of a bolted assembly and that the remaining 85% is simply air? This leads to gaps and the loosening of threaded connections.

Why are threadlockers important?

When fasteners loosen, this can cause serious accidents and a total shutdown of a production plant. Threadlockers add an extra level of protection by defending against improper tightening, shocks and vibration, thermal expansion and corrosion.

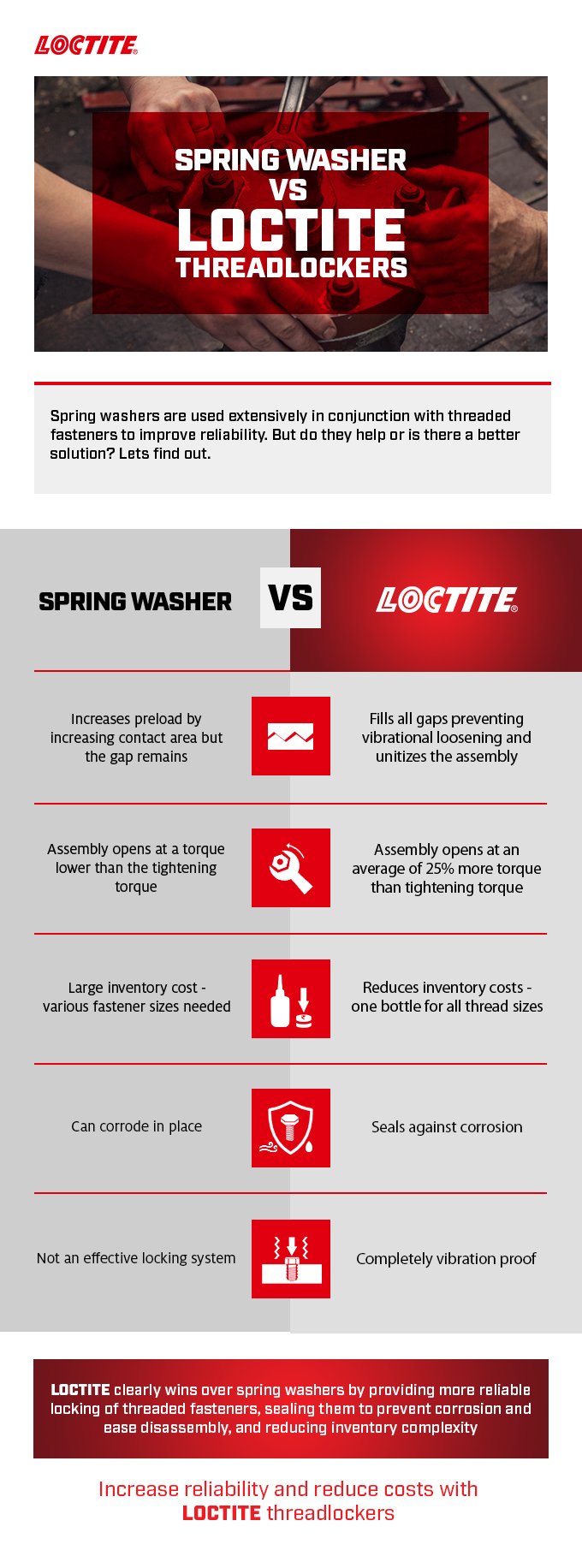

Unlike conventional fastening methods such as double nuts and spring washers, Loctite threadlockers maintain clamping force, fill all gaps and provide an air-tight seal.