Surface Preparation

Correct surface preparation is key before any bonding application, and the use of threadlockers is no different. Loctite recommend the use of Loctite SF 7063 to degrease and clean the threaded components prior to application.

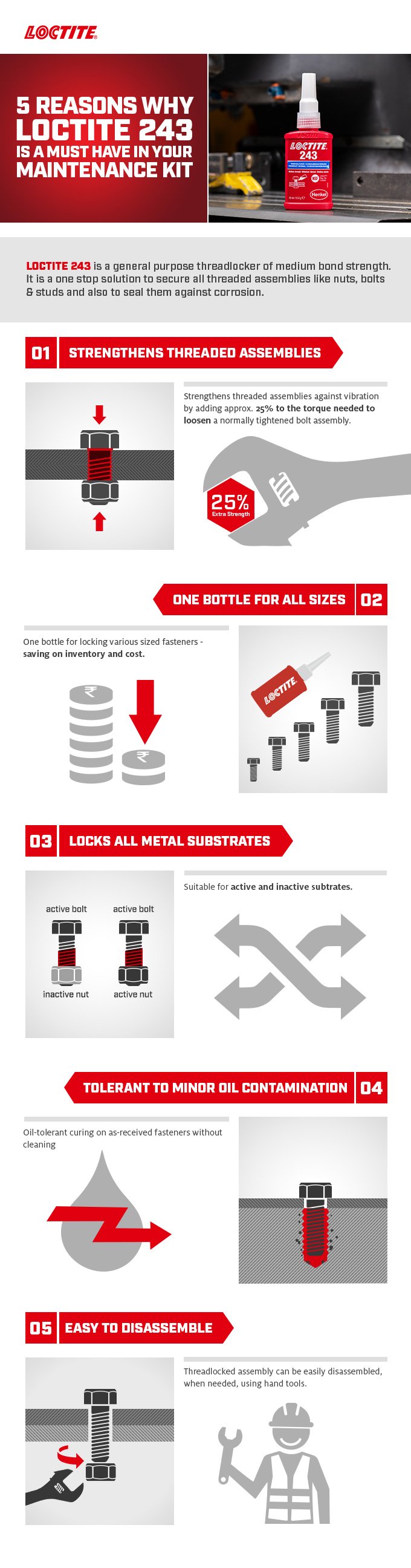

For over 60 years, Loctite have been producing a variety of threadlockers suitable for a wide range of applications. These so-called “red bottle” products can be applied in place of conventional fastening methods and help to prevent loosening of threaded assemblies, which in turn can lead to serious accidents and a total shutdown of a production plant.

Once you have selected the right threadlocker, you need to apply it in the appropriate way to reap its benefits.

Correct surface preparation is key before any bonding application, and the use of threadlockers is no different. Loctite recommend the use of Loctite SF 7063 to degrease and clean the threaded components prior to application.

If you are applying a Loctite threadlocker where cure speed is unacceptably long, or large gaps are present, it is recommended that an activator is used. Two products are available:

Loctite SF 7649 – A solvent based activator designed to promote the curing speed of Loctite anaerobic adhesives and sealants without any significant loss of joint strength. It is especially recommended for applications with passive metals or inert surfaces and with large bond gaps.

Loctite SF 7240 – A solvent free activator designed to promote the curing speed of Loctite anaerobic adhesives and sealants without any significant loss of joint strength. It is especially recommended for applications where the cure conditions are under 5°C.

To aid in the application of Loctite threadlockers, a range of dispensing equipment is available. This includes the Loctite Pro Pump Handheld Dispenser, suitable for both 50ml and 250ml sized bottles as well as dispensing needles in a variety of gauges that can be applied onto the dispenser or directly onto the bottles themselves.

For blind hole applications, drops of liquid threadlocker should be applied down the female threads into the bottom third of the hole and the bottom of the hole. To ensure complete coverage, it is suggested that threadlocker also be applied to the threads where they are engaged.

The rate of cure of a specific Loctite threadlocker will depend on a variety of factors, namely the use of an activator to aid the cure, the temperature conditions of the cure, the substrate that the threadlocker is to be applied to, as well as the product itself. Different products will have various cure times.

Please note, for locking plastic fasteners, Loctite recommends the use of Loctite instant adhesives.