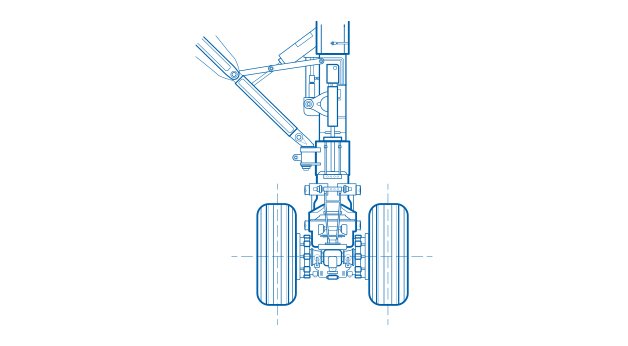

Although landing gear represents only 2.5% to 5% of the MTOW (maximum take-off weight) and 1.5% to 1.7% of an aircraft's total cost, it makes up around 20% of the maintenance cost of an aircraft during its lifespan. This is in part due to the extreme loads during take-off and landing, although additional factors such as temperature also result in a number of individual components requiring regular maintenance.

Ensuring landing gear operate efficiently throughout their lifetime is therefore vital, and Silmid provide a wide range of chemical consumables approved by manufacturers such as Safran Landing Systems and UTC Aerospace Systems.