Standard OEM Layout

Cabin interiors are all of the panels, trim and accessories inside the aircraft, including in the cockpit. The look and feel of a cabin can define the passenger experience, creating a sense of comfort and security that is part of any enjoyable flight.

AkzoNobel Aerospace Coatings' premium-quality airplane cabin interior coatings are designed to protect and enhance any aircraft’s internal appearance. Supported by outstanding durability, stain resistance and their team of in-house design experts, keeping a cabin looking fresh and modern has never been simpler. Their cabin interior products conform to EASA fire retardant regulations for use in interior aircraft.

We offer a wide range of airplane cabin interior solutions tailored to meet aerospace manufacturer and OEM requirements. Easily explore products by type - such as polyurethane topcoats, water-based finishes, or matte and gloss options - and access technical data sheets, brochures, and the Qualified Product List (QPL) to ensure the right choice for your project.

AkzoNobel Aerospace Coatings acquired Mapaero in 2019, a renowned specialist in structural and airplane cabin interior coatings, based in France. With particular focus upon sustainable, water-based and ecofriendly products, the acquisition has strengthened AkzoNobel Aerospace Coatings' position as an industry leader in coatings worldwide.

Types of Airplane Cabin Interior Coatings: Our range of airplane cabin interior solutions includes polyurethane topcoats for exceptional durability, water-based finishes for reduced environmental impact, and a variety of gloss levels to achieve the desired look and feel. Whether you need a matte finish for a refined passenger experience or a high-gloss surface for enhanced light reflection, AkzoNobel offers specialized coatings to meet the unique requirements of every aerospace application.

As part of the AkzoNobel/Mapaero acquisition, the AkzoNobel AeroFine 8250 Topcoat and AeroFine 8110 Sanding Surfacer were discontinued, with the FR2-55 family and process the recommended alternative.

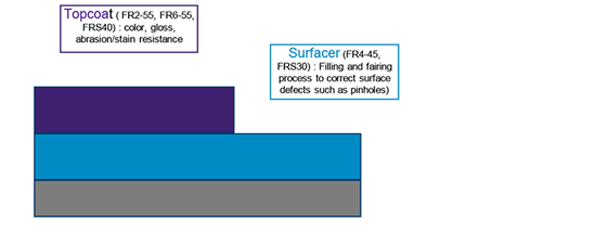

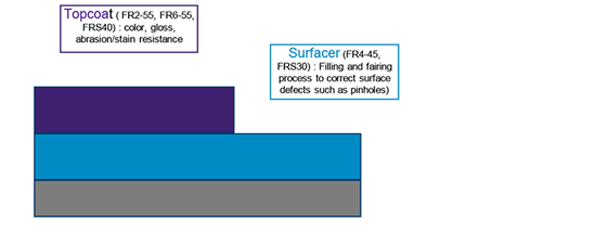

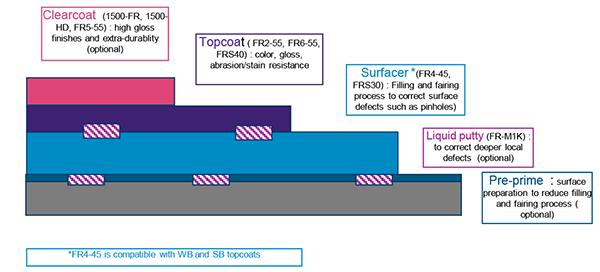

Following the correct process for your individual requirements is important, as there is no single product to properly paint an aircraft.

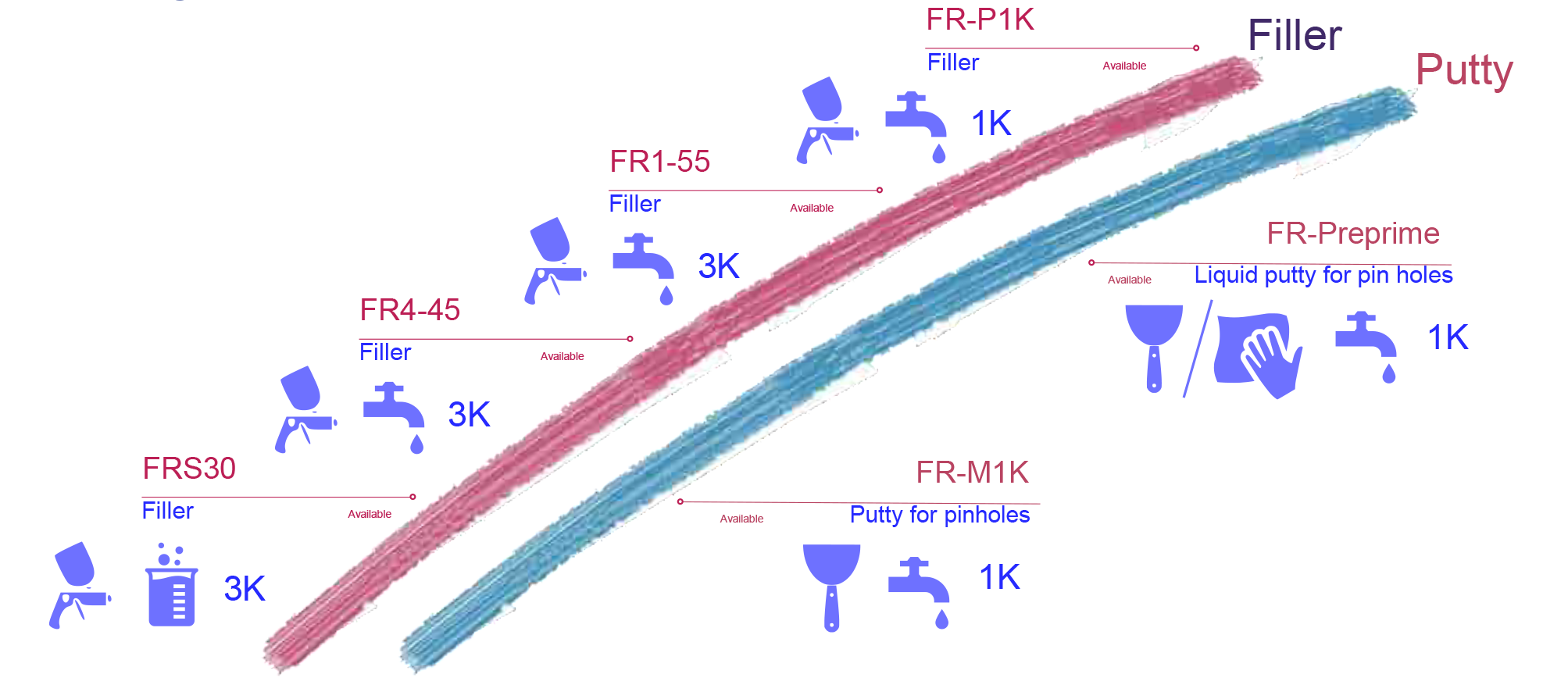

Application of FR4-45, FRS30 or FR-P1K filler

It depends on different parameters:

Is the color of the substrate close to the topcoat color? Does the plastic present pinholes ; parting lines or textured surface you need to get rid of?

If the answer to one of these question is yes, then a filler such as FR4-45 is needed.

If not, you can apply the topcoat directly on this plastic (after ensuring their good adhesion and compatibility.)

Application of F69 epoxy primer.

Primer must be cured at least at 40 °C before topcoat application. See F69 TDS for further details.